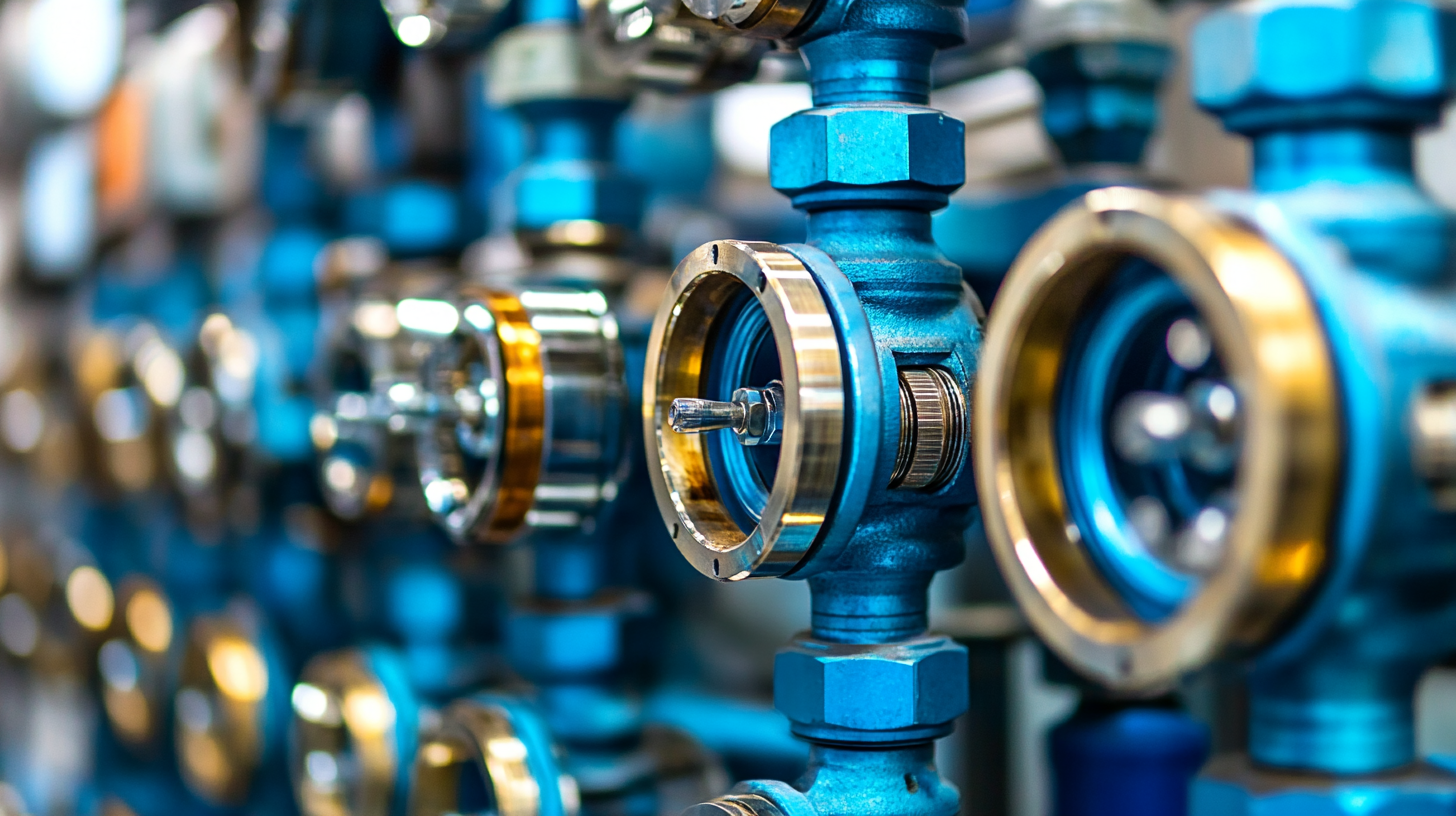

When it comes to plumbing and piping systems, selecting the right components is crucial for ensuring efficiency and reliability. Press fittings have emerged as a popular choice for joining pipes due to their simplicity and effectiveness. However, the wide variety of press fittings available can be overwhelming, especially for global buyers looking to make informed decisions. In this comprehensive guide, we will delve into the characteristics and applications of different types of press fittings, helping you navigate through the available alternatives.

From stainless steel to carbon steel options, understanding the key features and suitability of each type will empower you to choose the best press fittings for your specific needs. Join us as we explore the essential aspects to consider, ensuring that your piping solutions are both durable and efficient.

When navigating the press fittings market, understanding the importance of after-sales service is vital for global buyers. After-sales service extends beyond the initial purchase; it encompasses the support and assistance provided to customers post-purchase, ensuring their systems operate smoothly and efficiently. Quality after-sales service can help resolve issues quickly, prevent downtime, and maintain productivity, which is crucial for industries relying on these fittings.

Moreover, a reliable after-sales service can significantly enhance a company’s reputation. Buyers should look for manufacturers or suppliers who prioritize customer support and offer comprehensive services such as installation guidance, troubleshooting, and maintenance. The assurance of prompt responses and solutions fosters trust and can influence buying decisions. When considering options, it is essential to evaluate the level of after-sales support available, as it can be a deciding factor in long-term satisfaction and value for investment.

When considering press fittings, understanding the repair costs associated with these products is essential for global buyers. Various studies indicate that repair expenses for press fittings can vary based on several factors, including the material, application, and installation complexity. For instance, a report by Freedonia Group highlights that stainless steel press fittings, while more expensive upfront, can offer lower repair costs in the long run due to their durability and resistance to corrosion. Conversely, lower-priced options made from PVC may incur higher replacement costs over time, as they are more prone to damage.

Additionally, the complexity of installation plays a critical role in overall expenses. A survey conducted by the International Association of Plumbing and Mechanical Officials (IAPMO) revealed that improper installation can lead to increased failure rates, thereby escalating repair costs by as much as 70%. Therefore, investing in quality fittings and experienced installers can significantly reduce these potential costs. By evaluating these factors, buyers can make informed decisions that affect both the immediate budget and long-term maintenance expenses associated with press fitting products.

The manufacturing landscape for press fittings is witnessing a significant evolution driven by innovation and sustainability. Emerging technologies and material advancements are reshaping the way companies approach production, with an increasing focus on using eco-friendly materials that reduce environmental impact. Chemical companies are now leveraging scientific progress to design more sustainable options, aligning with broader goals for a greener economy. As outlined in recent industry outlooks, players in the oil and gas sector are also prioritizing sustainable practices along with capital discipline, signaling a shift towards responsible resource management.

**Tips:** When selecting press fittings, prioritize manufacturers who emphasize sustainability by utilizing recycled materials or offering energy-efficient solutions. Additionally, assess the long-term durability of fittings to ensure they contribute to waste reduction over time.

In a rapidly changing economic landscape, the integration of innovative technologies such as IoT and automation into manufacturing processes promises enhanced efficiency and lower environmental footprints. The aerospace and renewable energy sectors, for example, are at the forefront of adopting these technologies, which could pave the way for better supply chain sustainability across various industries.

**Tips:** Look for press fittings that incorporate smart technology, enabling better monitoring and management of resources. This can improve not only operational effectiveness but also align with customer expectations for sustainable and responsible products.

When selecting press fittings, global buyers must prioritize

material quality and

performance standards to ensure durability and reliability in various applications.

The choice of materials, such as

stainless steel,

copper, or

bronze, plays a crucial role in the longevity of the fittings. Buyers should consider the environmental factors—such as humidity, temperature, and chemical exposure—that the fittings will encounter.

For instance, stainless steel fittings are often favored for their corrosion resistance, making them ideal for outdoor or harsh conditions. In contrast, copper fittings may be preferred for their thermal conductivity in heating applications.

Performance standards are equally critical in the selection process. Buyers should look for fittings that comply with international standards, such as those set by the

American National Standards Institute (ANSI) or the

International Organization for Standardization (ISO). These standards ensure that the fittings have undergone rigorous testing for pressure handling, temperature variations, and leak prevention.

Moreover, checking for certifications from reputable third-party testing organizations can instill confidence in the quality of the products.

By carefully evaluating material quality and adherence to performance standards, global buyers can make informed decisions that meet their specific needs.

The press fittings market is poised for significant growth, driven by increasing demand for efficient and reliable piping solutions across various sectors. According to a recent report by Mordor Intelligence, the global press fittings market is projected to experience a compound annual growth rate (CAGR) of over 5% between 2023 and 2028. This growth is primarily fueled by the ongoing advancements in manufacturing technologies and the increasing adoption of press fitting systems in plumbing and HVAC applications. These innovations not only enhance installation speed but also improve joint integrity and reduce leak risks, becoming a preferred choice for contractors and builders alike.

In addition to market expansion, technological advancements are shaping the future of press fittings. The integration of smart technologies, such as IoT-enabled systems that monitor piping conditions in real time, is set to revolutionize maintenance practices. A report from Research and Markets highlights that the smart plumbing technology segment is expected to surpass $10 billion by 2025, representing a substantial portion of the press fittings industry. As these innovations continue to roll out, global buyers will need to consider not only the immediate cost but also the long-term benefits of investing in advanced press fitting solutions that promise greater efficiency and sustainability.

| Dimension | Material Type | Application Area | Market Growth Rate (2023-2028) | Technological Advancements | Recommended Standards |

|---|---|---|---|---|---|

| 1/2 inch | Copper | Plumbing | 5% | Smart connections | ISO 3506 |

| 3/4 inch | Stainless Steel | Heating Systems | 7% | Corrosion resistance technology | ASME B16.9 |

| 1 inch | Carbon Steel | Oil and Gas | 6% | Enhanced sealing mechanisms | API 6A |

| 1 1/4 inch | PVC | Drainage | 4% | Flexible joint systems | ASTM D1785 |

| 1 1/2 inch | Brass | Fire Protection | 8% | Modular fitting solutions | NFPA 13 |